As white goods accelerate their iteration towards frequency, conversion, intelligence, and high energy efficiency, ABL Semi recently launched an integrated MCU+IPM frequency conversion drive solution, covering mainstream home appliance scenarios such as frequency conversion refrigerator compressors, frequency conversion range hoods, and frequency conversion blenders. With its highly integrated architecture, low loss characteristics, and easy debugging advantages, it helps home appliance manufacturers reduce costs and increase efficiency while accurately matching the requirements of the new energy efficiency standards.

ABL Semi has developed three scenario-based solutions tailored to the differentiated load characteristics of white goods:

1. Variable frequency refrigerator compressor solution: Cortex-M0 core MCU + medium-power three-phase full-bridge IPM

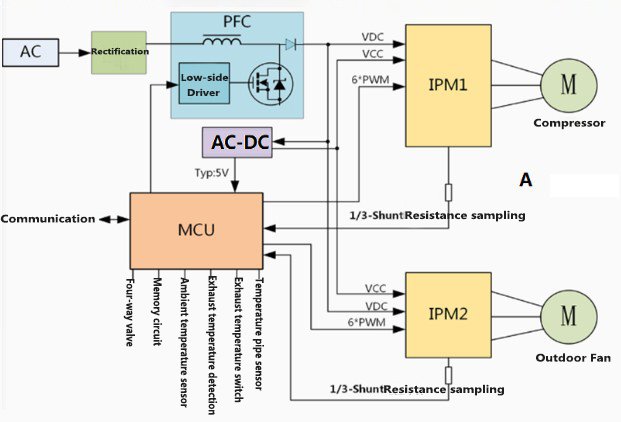

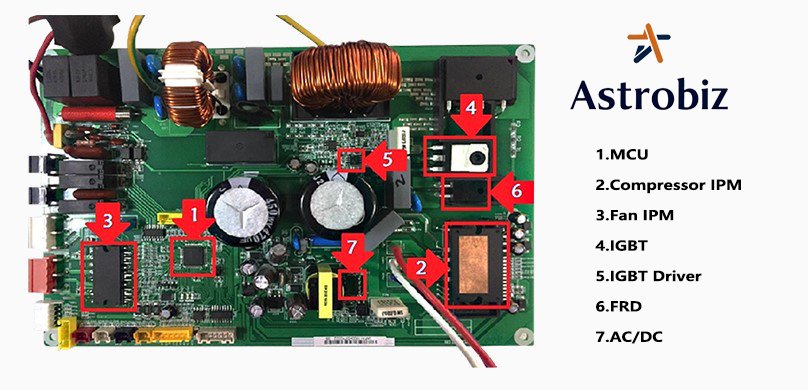

- Core Architecture: Employs a Cortex-M0 core MCU (with built-in motor vector control coprocessor) paired with a 600V/medium-power three-phase full-bridge intelligent power module (IPM);

- Solution Advantages: Supports single-resistor current sampling, achieves precise current control through a high-precision ADC, is compatible with high and low-pressure refrigerator compressors, and supports UART/SPI communication, enabling real-time information exchange between the panel and the drive system.

- Core Architecture: Employs an MCU integrating multiple UARTs and a high-speed ADC, paired with a 600V/medium-power three-phase full-bridge IPM;

- Solution Advantages: Supports sensorless FOC algorithm, enabling rapid start-up in both tailwind and headwind scenarios, compatible with multiple control modes such as constant speed and constant airflow, and adapts to different range hood motor models through offline parameter identification.

3. Variable frequency blender solution: High-speed control MCU + high-power three-phase full-bridge IPM

- Core Architecture: Employs an MCU with optimized high-speed motor control algorithms, paired with a high-current three-phase full-bridge IPM;

- Solution Advantages: Compatible with both Hall effect and Hall effect dual control modes (Hall effect-free solution reduces BOM costs), strong load capacity, startup speed ≤0.5s, suitable for the high-speed operation requirements of blenders.

Core Competitive Advantages: A Balance Between Performance and Cost

Compared to traditional discrete drive solutions, ABL Semi’s integrated solution boasts three major advantages:

- High Integration: The MCU integrates a motor control coprocessor, and the IPM integrates IGBTs and gate drivers, reducing external components by over 30% and simplifying product hardware design;

- High Energy Efficiency: The IPM utilizes low on-resistance technology, improving overall energy efficiency by 5%-8%, meeting new energy efficiency standards for home appliances such as GB/T 38375;

- Easy Debugging and Adaptation: A Turnkey software package is provided, supporting offline identification of multiple motor parameters, helping home appliance manufacturers shorten their R&D cycle by over 40%.

Compatibility: Covers mainstream white goods categories

This solution can be directly applied to multiple types of white goods:

- Refrigeration: Inverter refrigerators, inverter freezers;

- Kitchen: Inverter range hoods, inverter blenders, inverter food processors;

- Cleaning: Inverter dishwashers, etc.