In-depth Analysis of IGBTs: Technical Principles, Core Advantages and Industrial Applications | Professional Guide by ASTROBIZ LTD (ABL)

Introduction: IGBT ICs – The “Core Switches” in the Field of Power Electronics

In today’s rapidly evolving technological era, power electronics technology is ubiquitous – from the high-efficiency drive systems of new energy vehicles, to the stable operation of smart power grids, and the precise control of industrial automation equipment. Insulated Gate Bipolar Transistors (IGBTs), regarded as the “CPU” of power electronic devices, are playing an increasingly pivotal role.

IGBTs ingeniously integrate the advantages of Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) – high input impedance, easy drivability and fast switching speed – with those of Bipolar Junction Transistors (BJTs) – low on-state voltage drop and high current handling capability, emerging as a fully controllable, voltage-driven power semiconductor device. This unique composite structure enables IGBTs to operate stably under the complex working conditions of high voltage and large current, achieving efficient electrical energy conversion and control. They are thus widely applied in numerous critical fields such as new energy, power engineering, rail transit and industrial automation.

In the new energy sector, IGBTs serve as the core components of inverters in photovoltaic and wind power generation systems, responsible for converting direct current (DC) into alternating current (AC) and feeding green energy into the power grid. In power engineering, they are adopted in the flexible power transmission systems of smart grids, effectively improving power transmission efficiency and ensuring the safe and stable operation of the grid. In rail transit, IGBTs provide robust power for the traction systems of high-speed trains, subways and other rolling stocks, enabling their fast and smooth operation.

This article will subsequently conduct an in-depth analysis of the technical principles, prominent advantages, diverse application scenarios and key purchasing considerations of IGBTs, helping readers gain a comprehensive understanding of this critical device. As a professional supplier of power devices, ASTROBIZ LTD will also share industry insights and product recommendations in this article to support your project development.

Ⅰ. Core Technology: A Comprehensive Understanding of IGBTs

1.1 Definition and Core Structure

As insulated gate bipolar transistor integrated circuits, IGBTs are an extremely critical type of fully controllable, voltage-driven power semiconductor devices. At the micro level, their internal structure is exquisitely complex, consisting of four layers of semiconductor materials stacked in an orderly manner: the P-type substrate, N-type emitter layer, P-type base region and N-type collector region. This unique four-layer structure lays a solid foundation for the outstanding performance of IGBTs.

From the perspective of electrodes, IGBTs are three-terminal devices with three key ports: the gate (G), collector (C) and emitter (E). The gate acts as the “commander” of the device, precisely controlling the on and off states of IGBTs by applying voltage signals; the collector is responsible for collecting current and serves as a key node for current output; the emitter undertakes the important task of emitting carriers and works in coordination with the collector to ensure the smooth flow of current.

In practical applications, to meet the requirements of different scenarios, IGBT modules have emerged as the times require. They are usually packaged by bridging IGBT chips and FWD freewheeling diode chips through specific circuit topologies. The integration of FWD freewheeling diodes effectively solves the problem of reverse electromotive force generated by inductive loads at the moment of circuit on-off, protects the IGBT chips, and greatly improves the reliability and stability of the entire module, enabling it to operate stably in various complex power electronic systems.

1.2 Operating Principle: Switch Control Logic of Three States

The operating process of IGBTs can be subdivided into three states: cut-off, amplification, and saturation, each embodying unique electrical principles and control logic.

When the voltage UGE between the gate and the emitter is lower than the threshold voltage UGE(th), the IGBT operates in the cut-off state. In this state, the internal MOSFET channel cannot form, the base current of the transistor is completely cut off, and the current between the collector and the emitter is nearly zero. Acting like a “firmly closed gate” in the circuit, it blocks the passage of current and effectively interrupts electrical energy transmission.

As the gate voltage UGE gradually rises and exceeds the threshold voltage UGE(th), the IGBT enters the amplification state. Here, a channel is successfully formed within the MOSFET, supplying the base current for the transistor. This allows the collector current IC to change linearly with variations in the gate voltage UGE, functioning like a precise current regulator that finely adjusts the current according to the strength of the input signal.

When the gate voltage UGE continues to increase, causing the collector current IC to reach its maximum value and no longer change significantly with further rises in gate voltage, the IGBT shifts into the saturation state. At this point, the voltage VCE between the collector and the emitter drops to its minimum, the current peaks, and the IGBT acts as a closed switch, enabling the efficient transmission of electrical energy.

In practical power electronics applications, IGBTs primarily switch rapidly between the cut-off and saturation states to achieve on-off control of circuits. This “on-or-off” operating mode enables highly efficient electrical energy conversion and control, meeting a wide range of complex power demands. For instance, in inverters, IGBTs convert direct current (DC) to alternating current (AC) through fast switching actions, providing a suitable power supply for loads such as electric motors. In switching power supplies, the high-speed switching characteristic of IGBTs allows for stable voltage regulation, ensuring the accuracy and stability of the output

1.3 Core Advantages: Integrating the dual characteristics of MOSFET and BJT

IGBTs occupy a core position in the field of power electronics thanks to their integration of the dual advantages of MOSFETs and BJTs, which endows them with distinctive performance features.

IGBTs inherit the high input impedance characteristic of MOSFETs, meaning that only minimal control power is required to realize effective device control during the operation process, which greatly reduces the complexity and power consumption of drive circuits. Meanwhile, they boast the advantage of low on-state voltage drop inherent to BJTs: in the on-state, they can transmit large currents with a relatively low voltage drop, effectively cutting down on-state losses and boosting electrical energy conversion efficiency. This perfect combination of high input impedance and low on-state voltage drop allows IGBTs to deliver outstanding performance in high-voltage and large-current application scenarios, enabling efficient electrical energy conversion while mitigating system energy consumption and heat generation issues.

Compared with MOSFETs, IGBTs feature lower on-state resistance and can withstand higher current density, which effectively addresses the problems of high on-state losses and severe heat generation that plague MOSFETs in high-voltage and large-current applications. In contrast to BJTs, IGBTs require an extremely small drive current and feature simpler drive circuits that facilitate precise control, overcoming the shortcomings of BJTs such as complex driving and slow response speed.

IGBT modules also offer a host of additional advantages. In terms of parallel expansion, multiple IGBT modules can be easily connected in parallel to achieve the expansion of larger current capacity, meeting the application requirements of different power levels. In thermal design, IGBT modules adopt advanced packaging technologies that effectively enhance heat dissipation efficiency, ensuring the device temperature remains within a safe range even during long-term, high-load operation and thus guaranteeing system stability and reliability. Furthermore, IGBT modules have low lead inductance, which can effectively reduce electromagnetic interference (EMI) and improve the accuracy of signal transmission. The high parameter consistency of their internal chips ensures stable performance under different operating conditions and lowers the difficulty of system commissioning and maintenance.

Ⅱ. Industry Application Landscape: Key Sectors Empowered by IGBTs

2.1 New Energy Vehicles: Core Driving Device of the Power System

In the field of new energy vehicles (NEVs), IGBTs are undoubtedly the core of the core – hailed as the “cardiac pacemaker” of a vehicle’s power system, exerting a decisive influence on the overall performance of the vehicle.

In the motor drive system, as a key component of the inverter, IGBTs undertake the crucial task of accurately and efficiently converting the direct current (DC) output by the power battery into three-phase alternating current (AC). They supply a steady stream of power to the motor, ensuring the vehicle achieves smooth startup, acceleration and driving. Take the Tesla Model 3 as an example: its electric drive inverter adopts 24 Si-IGBT modules (supplied by Infineon), and the collaborative operation of these modules endows the vehicle with outstanding dynamic performance and driving range. BYD’s independently developed IGBT 4.0 modules are applied to the Han series models; compared with previous-generation products, their current carrying capacity has been increased by 30%, effectively boosting the vehicle’s power output and energy utilization efficiency.

The On-Board Charger (OBC) is a critical device for NEVs to realize AC charging, where IGBTs play a core role – they are responsible for converting 220V AC into high-voltage DC to charge the power battery. OBCs of different power levels, ranging from the basic 3.3kW model to the 22kW fast-charging model, all rely on IGBTs to achieve efficient and stable electrical energy conversion. The Direct Current/Direct Current (DC/DC) converter, on the other hand, uses IGBTs to convert the electrical energy of the high-voltage battery into 12V low-voltage electricity, powering numerous low-voltage devices in the vehicle such as lights, instrument panels and audio systems, and ensuring the normal operation of the on-board electrical system.

The high-efficiency energy conversion capability of IGBTs has greatly reduced the overall vehicle energy consumption and extended the driving range. Statistics show that the energy consumption of NEVs equipped with advanced IGBT modules can be reduced by 10%-20% compared with traditional vehicles. With the rapid development of the NEV market and the strong promotion of infrastructure construction such as charging piles under the “New Infrastructure Construction” policy, the NEV sector has become the core growth market for IGBTs, with market demand showing a trend of explosive growth.

2.2 Power Engineering and Smart Grid: The “Stable Switches” for Energy Transmission

In the field of power engineering and smart grids, IGBTs also play an indispensable and pivotal role, serving as core devices that ensure the stable transmission and efficient utilization of energy.

In frequency converters, IGBTs realize flexible regulation of AC frequency and voltage through fast and precise switching actions, thereby accurately controlling the rotational speed and operating state of motors. Equipment such as fans, water pumps and compressors widely used in the industrial sector can adjust power output in real time according to actual demand by matching frequency converters with IGBT ICs, achieving energy conservation and consumption reduction as well as improving energy utilization efficiency. For example, in large industrial plants, fan systems equipped with IGBT-based frequency converters can automatically adjust fan speed based on parameters such as indoor temperature and air quality, delivering an energy-saving effect of over 30% compared with traditional fixed-frequency fans.

As an important safeguard device for power systems, the Uninterruptible Power Supply (UPS) relies on IGBTs to rapidly convert battery DC to AC when the mains power is interrupted, providing continuous power supply for critical loads, ensuring normal equipment operation and avoiding serious consequences such as data loss and equipment damage caused by power outages. In places with extremely high requirements for power stability such as data centers, hospitals and financial institutions, UPS systems equipped with high-performance IGBT ICs can achieve millisecond-level switching time, guaranteeing the continuity and stability of power supply.

As a key technology for smart grids, ultra-high voltage (UHV) transmission leverages IGBTs to construct flexible DC transmission systems for voltage inversion and power regulation. China’s Zhangbei Flexible DC Grid Project adopts IGBT valve towers with a rating of 4500V/3000A, successfully realizing the long-distance and efficient transmission of large-scale clean energy and providing stable and reliable green power for the Beijing-Tianjin-Hebei region. Endowed with characteristics such as high reliability and a wide temperature adaptation range, IGBTs can operate stably in the complex and harsh working environments of power systems, meeting the stringent requirements of power systems for the long-term stable operation of equipment.

2.3 Rail Transit and Industrial Control: An Indispensable Choice for High-Power Scenarios

In the fields of rail transit and industrial control, IGBTs, by virtue of their outstanding performance advantages, have become the unparalleled choice for high-power scenarios, providing a solid guarantee for the efficient operation and precise control of equipment.

In rail transit traction systems, as core power devices, IGBTs are responsible for converting grid electrical energy into driving power suitable for train operation, enabling traction, braking and speed regulation control of trains. Take China’s Fuxing Hao high-speed trains as an example: their traction systems adopt 3300V IGBT modules, which feature high current density and low loss. These modules can provide strong and stable power for trains during high-speed operation, ensuring the safe, fast and smooth running of the trains.

In the field of industrial control, IGBTs are widely applied in scenarios such as industrial motor speed regulation and automation equipment. In industrial motor speed regulation systems, IGBTs realize soft start, speed regulation and energy-efficient operation of motors by controlling the power frequency and voltage of the motors, which effectively reduces the energy consumption and operating noise of motors and improves the operational efficiency and reliability of equipment. On automated production lines, IGBTs are used to control the operation of various automation equipment such as industrial robots and CNC machine tools, enabling precise positioning, rapid response and efficient collaboration of the equipment, and enhancing the automation level and production efficiency of the production lines.

The simplified connection function of IGBT modules in complex circuits has greatly reduced the integration difficulty of industrial equipment and improved the reliability and maintainability of systems. By integrating multiple IGBT chips and freewheeling diode chips into a single module, external wiring and connection points are reduced, which lowers the complexity and fault risk of the circuit and facilitates the installation, commissioning and maintenance of equipment.

2.4 Renewable Energy: Core of Energy Conversion for Photovoltaic and Wind Power

In the field of renewable energy, IGBTs act as the core of energy conversion in photovoltaic and wind power systems, providing key technical support for the efficient development and utilization of clean energy and serving as an important guarantee for achieving the global carbon neutrality goal.

In photovoltaic inverters, IGBTs undertake the core task of converting the direct current generated by solar panels into alternating current, enabling it to be smoothly connected to the power grid and supply clean electrical energy to society. Take Huawei’s SUN2000 series string-type photovoltaic inverters as an example: they adopt 1200V IGBTs, featuring high energy conversion efficiency and stable operational performance. Widely applied in numerous photovoltaic power plants worldwide, they have made an important contribution to promoting the popularization and development of photovoltaic power generation. Sungrow’s SG3500 centralized photovoltaic inverters, on the other hand, use 1700V IGBT modules, suitable for large-scale photovoltaic power plants and capable of achieving high-power and high-efficiency energy conversion.

In wind power converters, IGBTs also play a pivotal role, being responsible for converting the unstable alternating current generated by wind turbines into stable alternating current that meets the power grid’s requirements. ABB’s WindTEC wind power converters adopt 3300V high-voltage IGBT modules, which can adapt to complex wind power generation environments, realize efficient capture and conversion of wind energy, and ensure the stable grid connection of wind power. Through the efficient conversion between direct current and alternating current, IGBTs effectively support the grid-connected power generation of renewable energy and drive the large-scale application of clean energy. With the steady advancement of the global carbon neutrality goal, the market demand for IGBTs in the renewable energy sector is showing a trend of rapid growth, boasting enormous development potential in the future.

III. ASTROBIZ LTD (ABL-SEMI): IGBT Product Advantages – Delivering Customized Solutions for Industries

3.1 High-Performance Product Matrix: Covering Multi-Scenario Requirements

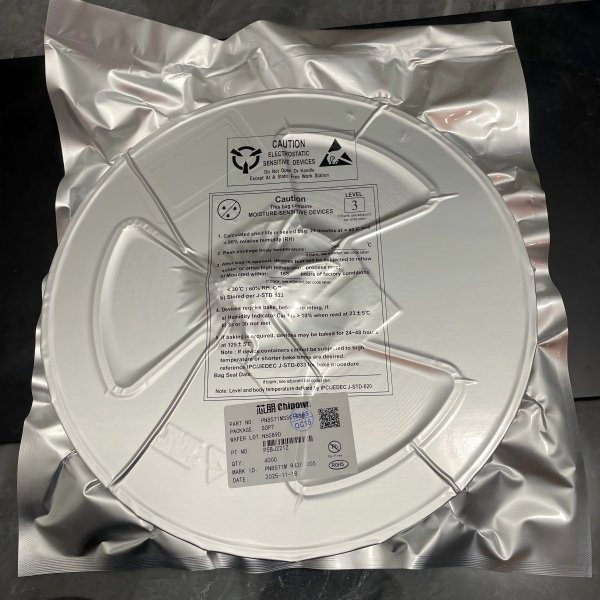

ASTROBIZ LTD (ABL) SEMI is committed to providing global customers with high-quality and high-performance IGBT products, and has built a rich and comprehensive product matrix to meet the diverse needs of different industries and application scenarios.

The IGBT products of ASTROBIZ LTD (ABL) SEMI come in a wide variety of types, including discrete IGBT modules, standard modules and Intelligent Power Modules (IPM). Discrete IGBT modules are suitable for applications with stringent space layout requirements and relatively low power needs, such as small household appliances and portable devices. Standard modules feature standardized design and packaging as well as high versatility, making them widely used in industrial control, renewable energy power generation and other fields. Intelligent Power Modules (IPM), on the other hand, integrate IGBT chips, drive circuits and protection circuits, boasting the characteristics of high integration and intelligence. They play a pivotal role in scenarios with extremely high requirements for system reliability and stability, such as new energy vehicles and rail transit.

In terms of voltage and current specifications, the IGBT products of ASTROBIZ LTD (ABL) SEMI deliver outstanding performance with an extremely wide coverage range. Its high-voltage modules can reach a rating of 3300V, meeting the high-voltage demands of UHV transmission, large-scale industrial equipment and other applications; high-current products can sustain several hundred amperes of current, providing robust power support for high-power motor drives, electric traction and other use cases. This extensive coverage of voltage and current specifications enables ASTROBIZ LTD (ABL) SEMI’s IGBTs to be adapted to various complex power systems, delivering tailored solutions for customers across different industries.

ASTROBIZ LTD (ABL) places paramount importance on product quality and reliability. Stringent control is exercised over every step of the production process to ensure high consistency of product parameters. Through advanced production processes and a comprehensive quality inspection system, every IGBT product undergoes multiple rounds of rigorous reliability tests, including high-temperature aging tests, humidity tests and vibration tests. This ensures that the products can operate stably in various harsh environments, providing a reliable guarantee for customers’ projects.

3.2 Customized Services: Adapting to Customers’ Exclusive Requirements

ASTROBIZ LTD (ABL) fully understands that significant differences exist among different customers in terms of application scenarios, technical requirements, cost budgets and other aspects. Therefore, leveraging its professional technical team and extensive industry experience, the company provides comprehensive customized services to meet customers’ exclusive needs.

For new energy vehicle customers, ABL’s technical team conducts an in-depth analysis of the specific technical requirements for their components including motor drive systems, on-board chargers (OBCs) and DC/DC converters, and carries out a full range of customized design covering IGBT module chip selection, circuit design, packaging forms and heat dissipation structures. For instance, in response to the demands for lightweight design and high efficiency of new energy vehicles, advanced packaging materials and heat dissipation technologies are adopted to optimize the structural design of IGBT modules, which ensures high performance while reducing the module’s weight and volume and improving energy utilization efficiency.

In the field of industrial control, tailored to the application characteristics of different industries such as industrial motor speed regulation and automated production line control, ASTROBIZ LTD (ABL) SEMI provides personalized IGBT module design and heat dissipation solution optimization. For high-power, high-speed industrial motor speed regulation systems, the switching frequency and drive circuits of IGBT modules are optimized to enhance the motor’s speed regulation accuracy and response speed. Meanwhile, efficient heat dissipation solutions are applied to ensure the temperature stability of IGBT modules during long-term, high-load operation, thus improving the system’s reliability and service life.

ASTROBIZ LTD (ABL) SEMI also boasts a comprehensive pre-sales technical support and after-sales response mechanism. In the pre-sales phase, professional technical personnel conduct in-depth communication with customers to understand their project requirements, provide detailed technical consulting and product recommendations, and assist customers in formulating the optimal solutions. In the after-sales phase, a 24/7 online technical service team has been established to respond to customers’ after-sales needs at any time, resolve problems arising during product use promptly, and provide comprehensive after-sales services such as technical training, maintenance and repair. This robust service system not only strengthens customers’ trust in the products of ASTROBIZ LTD (ABL) SEMI, but also provides strong support for the successful implementation of customers’ projects.

Ⅳ. IGBT Selection Guide: Avoid Selection Pitfalls and Precisely Match Requirements

4.1 Core Selection Parameters: Voltage, Current and Frequency

Precisely grasping key parameters is the foundation for ensuring perfect adaptation of IGBTs to application scenarios when making a selection. Among these, rated voltage, rated current and switching frequency are the most core considerations.

The selection of rated voltage must be closely aligned with the maximum operating voltage in the actual application scenario. For example, in ultra-high voltage (UHV) transmission projects, which involve power transmission at ultra-high voltage levels, it is usually necessary to select high-voltage IGBT modules with a rated voltage of up to 3300V or even higher to ensure stable operation in high-voltage environments and effectively avoid device damage caused by voltage overload. In contrast, for some low-voltage application scenarios such as frequency conversion control in small household appliances, IGBT modules with a rated voltage of 600V-1200V can meet the demand; an excessively high rated voltage will not only increase costs but also lead to performance redundancy.

The determination of rated current is equally crucial, requiring full consideration of load current and possible instantaneous overload conditions. Take industrial motor drives as an example: a motor generates an inrush current several times the normal operating current at the moment of startup. Therefore, the rated current of the selected IGBTs must be able to withstand such instantaneous overload to ensure the normal startup and stable operation of the motor. Generally speaking, to ensure system reliability, it is recommended to select IGBTs with a rated current 1.5 to 2 times the normal operating current.

Switching frequency directly affects the switching losses and efficiency of IGBTs, and different application scenarios have different requirements for switching frequency. In high-frequency application fields such as switching power supplies and frequency converters, it is necessary to select IGBTs with a high switching frequency to reduce switching losses and improve system efficiency. For instance, in high-frequency switching power supplies, using IGBTs with a switching frequency of up to 20kHz or higher can effectively reduce the volume and weight of transformers and improve the power density of the power supply. In occasions with low requirements for switching frequency, such as high-power welding machines, an excessively high switching frequency may cause additional electromagnetic interference (EMI) issues, and it is more appropriate to select IGBTs with a moderate switching frequency in such cases.

4.2 Module Type Selection: Discrete Modules vs Standard Modules vs Intelligent Power Modules (IPM)

IGBT modules are available in a wide variety of types, with discrete modules, standard modules and Intelligent Power Modules (IPM) being the most common ones. Each type has its unique advantages and applicable scenarios.

Discrete IGBT modules are packaged with a single IGBT chip and feature a compact size and high flexibility. In occasions with relatively low power demand and compact space layout, such as small household appliances and portable devices, discrete modules can give full play to their advantages, facilitating customized design to meet specific circuit requirements. Meanwhile, discrete modules have a relatively low cost, making them a cost-effective option for projects with limited budgets.

Standard IGBT modules are formed by packaging multiple IGBT chips and freewheeling diode chips in a specific circuit topology to create standardized module products. They have high versatility and are widely used in fields such as industrial control and renewable energy power generation. In industrial frequency converters, standard modules can be easily integrated with other circuit components to realize speed regulation control of motors. With mature production processes, stable performance and a reasonable price, standard modules are the first choice for most conventional application scenarios.

Intelligent Power Modules (IPM) are based on standard modules and integrate multiple functional units such as drive circuits, protection circuits and temperature sensors, boasting the characteristics of high integration and intelligence. In complex application scenarios with extremely high requirements for system reliability and stability, such as motor drive systems of new energy vehicles and traction systems of rail transit, IPM can effectively simplify system design and improve system reliability and safety. Through the built-in protection circuits, IPM can real-time monitor the operating status of the module and quickly take protective measures in the event of abnormal conditions such as overcurrent, overvoltage and overtemperature, avoiding device damage and ensuring the normal operation of the system.

When selecting a module type, users need to comprehensively consider various factors such as cost, integration difficulty and performance requirements. If a project has strict cost control and low power demand, discrete modules are a good choice; for conventional industrial applications, standard modules can not only meet performance requirements but also offer a high cost-performance ratio; while in occasions with extremely high requirements for system integration and reliability, Intelligent Power Modules (IPM) are the optimal choice.

4.3 Quality and Reliability Considerations: Choose a Professional Supplier

As core power devices in power electronic systems, the quality and reliability of IGBTs are directly related to the stable operation of the entire equipment. Therefore, it is crucial to select a professional and reliable supplier when purchasing IGBTs.

Professional suppliers with a comprehensive testing system such as ASTROBIZ LTD (ABL) SEMI can conduct comprehensive and multi-level rigorous tests on IGBTs. During the production process, strict control is exercised over every link from raw material inspection to chip fabrication and packaging and testing to ensure that products meet high-quality standards. Through advanced testing equipment and professional testing technologies, a full range of inspections are carried out on the product’s electrical performance, thermal performance and reliability. For example, high-temperature aging tests are conducted to simulate the product’s operating status in a long-term high-temperature environment and verify its stability; humidity tests are carried out to evaluate the product’s performance in humid environments; vibration tests are performed to inspect the product’s reliability in vibrating environments. Only products that pass these rigorous tests can enter the market and provide reliable guarantees for customers.

Quality certification is also an important indicator for measuring the reliability of a supplier. Obtaining quality certifications issued by internationally authoritative certification bodies, such as the ISO 9001 Quality Management System Certification and UL Certification, means that the supplier has met international standards in product quality control and production management, and the quality and reliability of its products have been widely recognized.

The heat dissipation design of the product should also not be ignored. IGBTs generate a large amount of heat during operation; inadequate heat dissipation will lead to excessively high device temperature, which in turn affects its performance and service life. High-quality IGBT products usually adopt advanced heat dissipation technologies, such as optimized heat dissipation structure design and the application of high-efficiency heat dissipation materials, which can effectively improve heat dissipation efficiency and ensure that the device temperature remains within a safe range during long-term, high-load operation.

Paying attention to the long-term operating life of the product is also one of the key points in selecting IGBTs. A long and stable operating life can reduce equipment maintenance costs and improve equipment utilization efficiency. Professional suppliers will continuously improve the long-term reliability of products and extend their service life by optimizing product design and improving production processes.

When selecting an IGBT supplier, priority should be given to professional suppliers such as ASTROBIZ LTD (ABL) SEMI, which have a comprehensive testing system, obtained authoritative quality certifications, and attach great importance to heat dissipation design and the long-term operating life of products. This ensures that the purchased IGBTs can meet the high-performance and high-reliability requirements of the project and provide a solid guarantee for the stable operation of the equipment.

Ⅴ. FAQ: Answering Common Questions About IGBTs

5.1 What Are the Core Differences Between IGBTs and MOSFETs?

While both IGBTs and MOSFETs are important power semiconductor devices, they exhibit distinct differences in several key aspects. In terms of device structure, IGBTs are hybrid devices composed of BJTs (Bipolar Junction Transistors) and MOSFETs, featuring a unique four-layer semiconductor structure that endows them with excellent high-voltage and large-current carrying capabilities. MOSFETs, by contrast, are unipolar devices with a relatively simple structure, conducting current primarily through majority carriers (electrons or holes).

In terms of driving method, IGBTs are voltage-driven devices: only a certain voltage signal needs to be applied to the gate to control the on and off states of the device, with low drive power required. MOSFETs are also voltage-driven, but their large input capacitance means that in high-frequency applications, a larger drive current is needed for rapid charging and discharging to ensure fast device response.

From the perspective of applicable scenarios, IGBTs deliver outstanding performance in high-voltage and high-power applications thanks to their high-voltage and large-current handling capabilities and low on-state voltage drop, such as motor drive systems of new energy vehicles, UHV transmission in power engineering, and high-power motor speed regulation in industrial control. MOSFETs, meanwhile, with their fast switching speed and high operating frequency, are more suitable for low-voltage and high-frequency application scenarios, such as switching power supplies, high-frequency induction heating, and communication power supplies where frequency requirements are high. For example, in the switching power supply of mobile phone chargers, MOSFETs can operate at a high switching frequency, effectively reducing the volume and weight of transformers and improving power supply power density; in the inverters of new energy vehicles, IGBTs can withstand high voltage and large current to ensure efficient and stable motor driving.

5.2 What Precautions Should Be Taken for the Installation and Use of IGBT Modules?

The close attachment of the heat sink is crucial when installing IGBT modules. First, select a radiator of appropriate size and material to ensure its heat dissipation area matches the power of the IGBT module. During installation, ensure the radiator’s surface finish meets requirements to reduce contact thermal resistance. A proper amount of thermal grease can be evenly applied between the radiator and the module, with the thickness strictly controlled—0.1–0.2mm is generally optimal, as excessive or insufficient thickness will impair heat transfer efficiency. Tighten the screws with the correct torque in accordance with the values specified in the product manual: insufficient torque may increase thermal resistance and cause screw loosening during equipment operation, while excessive torque may damage the module housing or compromise its insulation performance.

Wiring specifications are equally important and cannot be ignored. Always disconnect the power supply before wiring, and use a multimeter to check if the module is discharged to ensure operational safety. Correctly identify the three terminals of the IGBT module—the gate, collector and emitter: the gate is usually used to input low-current control signals to control switching actions; the collector is connected to the high-voltage source as the main power input terminal; the emitter serves as the output terminal, connected to the ground or load circuit. When connecting control signal wires to the gate terminal, tighten the screws without overexertion to prevent thread damage. When connecting the collector and emitter, first connect the collector to the positive power supply, then the emitter to the ground or load, ensuring no wire crossing to avoid short-circuit risks.

During operation, operation beyond rated parameters must be strictly avoided. Select an IGBT module with appropriate rated voltage and current based on application requirements, ensuring the rated voltage matches the input power supply voltage and the rated current fully accounts for steady-state losses and switching losses. For example, in motor drive applications, a motor generates a large inrush current at startup, so the rated current of the selected IGBT module must be able to withstand such instantaneous overload to ensure normal system operation. At the same time, pay close attention to controlling the module’s junction temperature (Tj), ensuring it remains below the maximum junction temperature (Tjmax) at all times to avoid thermal fatigue caused by excessive temperature, which would shorten the product’s service life. Enhanced heat dissipation can be achieved through rational heat dissipation design and the installation of cooling fans to maintain the module’s normal operating temperature.

5.3 What Are the Future Technological Development Trends of IGBTs?

From the perspective of new material applications, Silicon Carbide (SiC) hybrid devices are gradually becoming a research hotspot. Silicon carbide boasts excellent characteristics such as a wide bandgap, high breakdown electric field and high thermal conductivity; combining it with IGBT technology can effectively enhance device performance. For instance, SiC-IGBT hybrid devices are expected to achieve higher operating voltages, lower on-state resistance and faster switching speeds, further improving the efficiency and power density of power electronic systems. Such new hybrid devices will have broad application prospects in fields such as smart grids and new energy vehicles, and better meet the future demand for efficient and reliable energy conversion.

Structural optimization is also an important development direction for IGBTs. Field-Stop IGBTs (FS-IGBTs) effectively reduce turn-off losses and improve switching speed through internal structural optimization. In the future, as performance requirements for devices continue to rise, similar structural optimization designs will continue to emerge: by improving internal electric field distribution, carrier transport mechanisms and other aspects, device losses will be further reduced and their comprehensive performance enhanced.

Increased integration is also an irresistible trend. Intelligent Power Modules (IPMs), which highly integrate functional units such as IGBT chips, drive circuits, protection circuits and temperature sensors, are expected to achieve a higher degree of miniaturization and intelligence in the future. Further optimizing integration processes to reduce module volume and weight, while improving their reliability and stability, will enable them to play a greater role in new energy vehicles, industrial automation and other fields. For example, in the motor drive systems of new energy vehicles, miniaturized IPMs can save space, improve system integration and reduce costs.

In the field of New Infrastructure, such as 5G base station construction, UHV transmission, and new energy vehicle charging piles, IGBTs, as key power devices, will face surging market demand. With continuous technological progress, IGBTs will provide strong support for the development of New Infrastructure with higher performance and lower costs, driving technological innovation and industrial upgrading in various fields.

Conclusion: Seize IGBT Opportunities and Choose a Professional Partner

As core devices in the field of power electronics, IGBTs, with their unique technical advantages and outstanding performance, are widely applied in key industries such as new energy vehicles, power engineering, rail transit and renewable energy, becoming a key driving force for energy transition and industrial upgrading. From technical principles to application scenarios, from product selection to future trends, we have conducted an in-depth analysis of all aspects of IGBTs, and we believe you have gained a comprehensive and in-depth understanding of this critical device.

In the selection process, by focusing on core parameters such as voltage, current and frequency, combining the characteristics of discrete modules, standard modules and intelligent power modules, and choosing a professional and reliable supplier, you can precisely match your needs and ensure the efficient operation of your projects. ASTROBIZ (ABL) SEMI, with its high-performance product matrix, customized services and comprehensive quality assurance system, is committed to providing you with the optimal IGBT solutions.

Faced with the wave of global energy transformation and industrial intelligence development, the IGBT market boasts broad prospects and boundless opportunities. Consult ABLSEMI now to obtain exclusive IGBT solutions, work together to seize market opportunities, and jointly promote the innovative development of the industry! For more product information, please click on the product page or leave a message for consultation—we look forward to cooperating with you!

CTA (Call to Action)

Ready to dive deeper into the world of IGBTs and precisely match your project needs? Take action now!

Click “Browse ASTROBIZ(ABL) SEMI‘S IGBT Product Catalog” to explore a wide range of high-performance products for your selection.

If you have custom requirements, click “Submit Requirements for Tailored Solutions” – the professional team at ASTROBIZ (ABL) SEMI will craft exclusive, custom-fit solutions for you.

Also, feel free to share this insightful guide on social media! Click the share buttons below to connect and discuss with industry peers, and drive the advancement of technology together.